Bulk cargo liquefaction

There are numerous scientific research projects, articles, advice, and comprehensive descriptions of bulk cargo liquefaction. Our monthly theme highlights the most relevant information and encourages operators of bulk carriers (especially of smaller vessels) to refresh their existing knowledge and read the latest articles for updated details and further insights.

During the last decade, on average 10 bulk carriers have been lost at sea each year due to cargo liquefaction. Cargo liquefaction is a well-known risk associated with solid bulk cargoes. Cargoes considered as prone to liquefaction are typically characterized as fine-grained, non-cohesive (the grains remain separated), loosely packed, and wet granular materials. During liquefaction the material changes from a solid to a liquid state, which can cause the vessel to list, suffer structural damages, or even capsize.

It could take as little time as five minutes from when liquefaction is detected, if it is detected at all, until the vessel has capsized. In other words, there might be very little time for remedial measures or safely evacuating the vessel.

Underlying reasons:

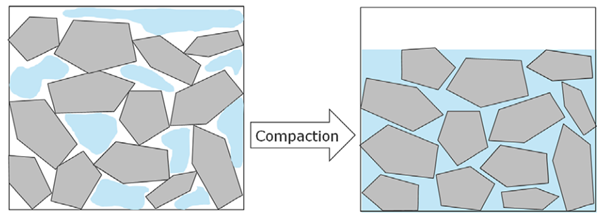

Solid bulk cargoes are normally two-phase materials with layers of water and air between the solid particles. When the particles are in contact with each other, the friction between them makes the material act like a solid (even though there is liquid present). But when the water pressure rises, due to compaction caused, for example, by vessel movements, engine vibration, or water ingress through leaking hatch covers, friction is degraded to zero and the material acts like a liquid (even though the solid particles are still present).

Source: Guideline for the design and operation of vessels with bulk cargo that may liquefy, DNV 2019

Liquefaction involving granular materials is most likely to occur shortly after loading, and typically only parts of the cargo will be liquefied at the same time, which in most cases leads to partial liquefaction. The liquefied state is a temporary state that usually lasts for a limited time. After a while, the cargo again settles into a more compact state, but usually it will not return to its original trim i.e., the cargo will remain in the position into which it shifted:

Source: Cargo liquefaction in bulk carriers: a review, Van Paassen et.al. 2016

In the case of very fine, clay-like materials, the liquefaction mechanism is principally different from that of granular materials. Unlike liquefaction of granular materials, where increased pore water pressure is the cause, liquefaction of clay-like materials can be seen as a fatigue of the material. Following numerous stress cycles due to vessel motions, wave impacts and other vibrations, the structure and the strength of the material are suddenly reduced. Since numerous stress cycles are required, liquefaction problems typically occur several days or weeks after loading.

The likelihood of cargo liquefaction resulting in the loss of vessel stability correlates with vessel size; larger vessels e.g., Capesize (> 125 000 DWT) experience considerably lower accelerations than Handymax (50 – 60 000 DWT) or Handysize (< 25 000 DWT) vessels. Another important factor is that shifting cargo in larger vessels results in lower listing angles. This correlates with the related casualty data, which is mostly linked to relatively small vessels.

Mitigating actions:

Know your cargo! It is not uncommon that shippers present cargoes with their trading names. The cargo should always be described by Bulk Cargo Shipping Name (BCSN) according to the International Maritime Solid Bulk Cargoes Code (IMSBC) to raise awareness and enable early detection of the risks associated with the cargo.

To avoid increased moisture in cargo, hatch covers should be kept closed during heavy rain, except when opened for loading. Both during loading and voyage, the cargo in the holds should be monitored for excess water or other signs of liquefaction risk, such as flattening of the cargo or fluid flow. In addition, hatch cover maintenance and watertight integrity should be ensured according to manufacturer’s instructions.

Appoint a surveyor or cargo specialist. It is often difficult for the crew to determine the actual condition of the cargo (moisture contents, other safety impacting cargo characteristics).

Best practices:

To reduce short rolling period, when the loading conditions and the structural strength of the vessel allow it, the centre of gravity of the vessel could be raised by ballasting the top wing tanks or by loading cargo in a non-homogeneous pattern.

Liquefaction is most often caused by heavy rolling with large rolling amplitude and short rolling period; hence, weather routing is recommended to avoid excessive motion.

Additional information:

International Maritime Solid Bulk Cargoes (IMSBC) Code (imo.org)